MFDC Resistance Welding Applications

From the white appliances to automotive sub industry, we build systems that increase the production quality; and reduce costs by less energy consumption using MFDC welding technology.

Mechanic Automation /Robotics Department-Automation Systems

Mainly in white appliances, automotive and subsidiary industries, we can produce turnkey systems with low energy costs by using MFDC welding technology.

.jpg)

Assembly Line Applications

Mechanic Automation /Robotics Department-Automation Systems Department

We can design assembly lines from start to finish with MTPRO software. We complete the installation of the lines we designed as soon as possible and install the lines with the purpose of high efficiency.

Using ready components, we can design a complete assembly line with the MTPRO software. Subsequently we assemble and activate it in a short span of time, thus installing high efficiency lines.

HKTM develops projects that are compatible with Bosch Rexroth’s assembly lines thanks to their experience of over 20 years. We initiate and install projects of systems that consume less energy and have increased efficiency with manual production systems and transfer systems.

.jpg)

Linear Modules

Mechanic Automation /Robotics Department-Automation Systems Department

We produce solutions depending on rate, load and stroke with screwed compact solutions that have triggers, rack and pinions. In the modules we use, we present quality and solutions with Bosch Rexroth products.

We provide optimum solution according to speed, load and stroke with compact solution containing timing belt, gear rack and threaded rod for linear transfer applications.

.jpg)

Silicone Dosing Systems

Mechanic Automation /Robotics Department-Automation Systems

It is used in various industries from silicone dosing systems automotive sector to construction and from defense industry to production of electronic components.

This is the process of transferring fluid mixture obtained by mixing two different fluid substances in stated and desired amounts using suitable valve or gun systems. Mixing and dosing systems are systems used in the application of fluids described as two components used especially as adhesion or sealing elements in industry.

It is used in various industries from automotive to construction and from defense industry to production of electronic components.

Use of this type of systems allows the capture of desired mixture in high precision. It allows this ratio to be constant throughout the entire process. System automatically adjusts material flows and pressures precisely for you to achieve a constant series. As a result, less material is wasted, scrap and reprocessing conditions are minimized.

System basically consists of the following equipment;

Dosing Injection System

Feed Pumps

Hoses

Materials Application Tool (Valve or gun)

Fluid Regulator

.jpg)

Lubrication Systems

Mechanic Automation /Robotics Department-Automation Systems

One such product that we in our wide range of products we have in stock is Graco's automatic lubrication systems, of which we are a dealer. It is ready to be supplied immediately for use in appropriate projects.

Automatic Lubrication Systems

Industrial machinery/tools/equipment and attachments must be regularly lubricated to extend their lifecycles and provide problem-free operation. Each equipment requires a different lubrication and excessive lubrication is a wrong and unnecessary application as much as insufficient lubrication.

What is Friction?

Friction is the force between two objects in contact and the force resisting this action. Movement is not a must for this force to occur. However, friction force during movement (kinetic) is different from cases when there is no movement (static). Friction causes heat and expansion. Irregular expansion may cause fracture or break as two surfaces are in contact.

What is Lubricant?

A substance that reduces friction between two surfaces, protects against heat and breaks and forms a layer between these surfaces.

What is Layer?

Layer is the lubricant layer between two surfaces. It allows two surfaces to integrate at a certain level. (Nominal value is 0.001 inch-0.025 mm)

Viscosity

Viscosity affects the creation of the film. Lubricant thickens at low temperatures and cannot be transferred after a while. At high temperatures, it gets thinner and gets through sealing elements and/or may lose its ability to hold on to the surfaces.

NLGI Grease Classification

Why Lubrication?

Lubrication is carried out due to 6 basic reasons;

- Friction reduction

- Wear reduction

- Shock and vibration reduction

- Temperature drop

- Corrosion prevention

- Contamination prevention

Why Automatic Lubrication?

Lubrication that is neither too little nor too much in small but necessary quantities at regular times.

Automatic Lubrication System Design

1. Lubricant Selection

- Oil

- Grease (According to NLGI classifications)

- Buna-N or Viton sealing elements

2. Power source selection

- Manual

- Mechanical

- Pneumatic

- Hydraulic

- Electricity (required voltage)

Selection Of Control System

- Manual/Visual

- Machine Control (PLC)

- Cycle control

- Timer control

Determination of System Requirements

- Drawing the machine

- Determination of lubrication points

- Calculation of oil requirement for lubrication points

- Planning lubrication installation

Selection of Measurement Devices

- Distribution blocks

- Injectors

- Types of thread; SAE, NPT, BSP, Metric

Accessory selection (for feedback) Lubricating Pump Selection

- Manual or Mechanical

- Pneumatic, Hydraulic or Electric

- Pump capacity (Reservoir capacity, type)

- Determination of required pressure

- Determination of required output amount

- Low level switch, monitoring, feedback and so on.

.jpg)

Power Transmission Systems

Mechanic Automation /Robotics Department-Automation Systems

Couplers is a must for power transmission systems. We are able to provide all power transmissions required for any applications in the engineering using our couplers of various specifications.

1. Coupling Selection and Things to Pay Attention in Power Transmission Systems

Fittings called COUPLINGS have been used to transmit power and connect drive elements to each other for a long time. Especially in our country, low-cost fittings that do not comply with standards have been used for drive systems for a long time. As complicated, expensive and important power transmission systems have been popular recently, quality couplings that conform to standards have started to be reviewed in more detail. Therefore, selection of the most suitable coupling has been one of the priorities in R&D.

Besides, couplings, which act as a fuse for power transmission elements such as motor, pump or reducers, have made users feel this function more and more day by day and allowed a precise and successful torque-power transmission by compensating axial, angular and radial offsets.

As mentioned above, coupling selection is highly significant for the whole system. Also, they act as a low-cost fuse element compared to the whole system. Things to consider for a correct coupling selection and the coupling selection process are described below.

Coupling is a component that transfers the rotating movement generated in a power source (motor, etc.) to another system (reducer, machine, pump, conveyor band, etc.). Besides rotation, couplings;

- Should not cause loss of power

- Should damp vibrations

- Should not transfer potential knocks to the power supply (motor, etc.)

- Should break in case of overload and act as a fuse that protects the motor or other components

2. Coupling Selection

2.1. Couplings are selected according to two torque values.

TKN= Nominal Torque

TKmax= Maximum Torque

HKTM – Mechanical Automation and Sales - Power Transmission Systems (Couplers, Gears)

2.2. Drive is calculated according to nominal torque value.

TN=9550 X P(kW)/n(rpm)

TKN≥ TN X St

HKTM – Mechanical Automation and Sales - Power Transmission Systems (Couplers, Gears)

2.3. For maximum torque

TKmax≥ Ts X Sz X St + TN X St

Drive side torque Ts=TAS X MA X SA

Torque on the driven side Ts=TLS X ML X SL

MA= JL/( JA+ JL) M= JA/( JA+ JL)

3. Example Coupling Selection

Driving Side

Electric motor size = A.C. Motor 315 L P= 160 kW

Speed (n) = 1485 rpm

Inertia Torque on Drive Side (JA) = 2.9 kgm2

Initial frequency (z) = 6 1/h Sz= 1.0

Ambient Temperature = 60°C St=1,4

Driven Side

Screw Compressor Nominal Torque (TLN) = 930 Nm

Inertia Torque on Driven Side (JL) = 6.8 kgm2

Calculation

TAN (Nm)= 9550 X PAN (kW)/nAN (rpm)

TAN= 9550 X 160/1485=1029 Nm

TKN≥TLN X St

TKN≥ 930 X 1.4 = 1302 Nm

The coupling that has the closest higher value to the resulting Nominal Torque value can be selected. Another thing to consider here is the TKmax value. Maximum torque value is usually twice as nominal torque.

4. Conclusion

Power transmission systems used today are similar to a human heart for all industries. Elements running on this system must be carefully and meticulously selected, run for long years and must not cause stoppages. Couplings are essential for these systems and at the same time they are affordable insurance tools. Choosing the correct coupling is an issue that increases and affects the efficiency and health of the system.

.jpg)

Reducers

Mechanic Automation /Robotics Department-Mechanical Products

The reducers that we choose to use for our projects are reducers that are compatible with each sectors’ properties and each drive output interface, design and installation.

They can be described as generally closed, gear systems used to reduce high speeds resulting from drivers such as fixed speed electric motors to revolution speeds required by machines or change the direction of movement. Reducers are structurally power transmission systems consisting of gear systems, gears, shafts, gear bearings as part of power transmission systems placed in body gear box. Although reducers vary depending on gear types they have, Planetary Gear Reducers are commonly used types. The most important reasons for this are smaller inertia moment of rotating masses of planetary gears, their compact structure so they take up less space and capability to work on high speed efficiently. Another important reason is the low gear gaps (low backlash).

Areas of Application

- Automotive

- White Appliances

- Medical products

- Machinery manufacturing

- Food

Reducer Selection

Main factors that determine the type of product to be used are machine's working conditions, heat and the load to be applied to reducer shaft.

- Reducer body type

- Motor power

- Output speed

- Motor connection method

- Load class

- Daily operation hours

- Number of hourly start-stop

- Cycle ratio*

*Number of reducer input speed = Number of engine speed: n1 = nm = 1460 RPM

Number of reducer output speed = Number of construction machinery speed: n2 = niche = 23 d/d

Reducer cycle ratio: i = n1 / n2 = 1460 / 23 = 63 / 1

.jpg)

Mega Cartesian Robots

Mechanic Automation /Robotics Department-Automation Systems

Increasing production efficiency with mega-cartesian robot solutions that can be customized for different needs. We produce tailor-made solutions with the modular solutions we have developed.

We are increasing the production efficiency through mega-sized custom Cartesian robots for systems where several production machines work in the same production hall, just as in the plastic injection sector. The modular solutions we develop can be reshaped according to customer requirements and specialized for different needs.

.jpg)

Transfer Systems

Mechanic Automation /Robotics Department-Automation Systems

Thanks to KRS series robots, dynamic servo motors of Bosch Rexroth and our expertise in quality control, we produce transfer systems that work flawlessly under any condition.

Thanks to the dynamic servo motors, high precision linear movement components and engineering of Bosch Rexroth, KRS series robots that we have designed for plastic injection machines are able to keep their pace and positions for each cycle at pick and place, insert placement and quality assurance applications.

.jpg)

Safety Lock Systems

Mechanic Automation /Robotics Department-Mechanical Products

We can come to your aid whenever you need it with our wide range of products from 1 ton to 85 tonnes driven and pneumatic-driven security lock systems depending on the product type.

As time progresses, with our increasing integration especially in Europe and the World, Security has been gradually becoming increasingly important. Positive measures have been implemented in terms of job and staff security and health on the basis of both state and private organizations. Besides, manufacturers aim to expand equipment and machine lives by developing various products and applications related to machine and equipment safety as well as provide safety for staff working with the machine. Locking systems developed for the safety of moving cylinder equipment carrying loads can especially be used with bot hydraulic and pneumatic drive systems. For example, for a hydraulic press, locking mechanisms mounted on auxiliary cylinders pre-installed on press are immediately activated in case of a potential emergency in hydraulic power unit of the press or in hydraulic cylinders that move the top plate and hold the top plate and mold weights, thus they will protect the machine and the operator from damage.

Another advantage of the locking systems is the ability to safely lock the top plate along the stroke during maintenance.

Safety locking units are available in different capacities for loads with different weights. Most commons are from 1 ton to 85 tons for hydraulic driven ones, and from 1 ton to 22 tons for pneumatic driven ones. A single mechanism can be applied to the same system. Depending on the machine design, two or more mechanisms can be mounted and the load holding capability can be increased.

.jpg)

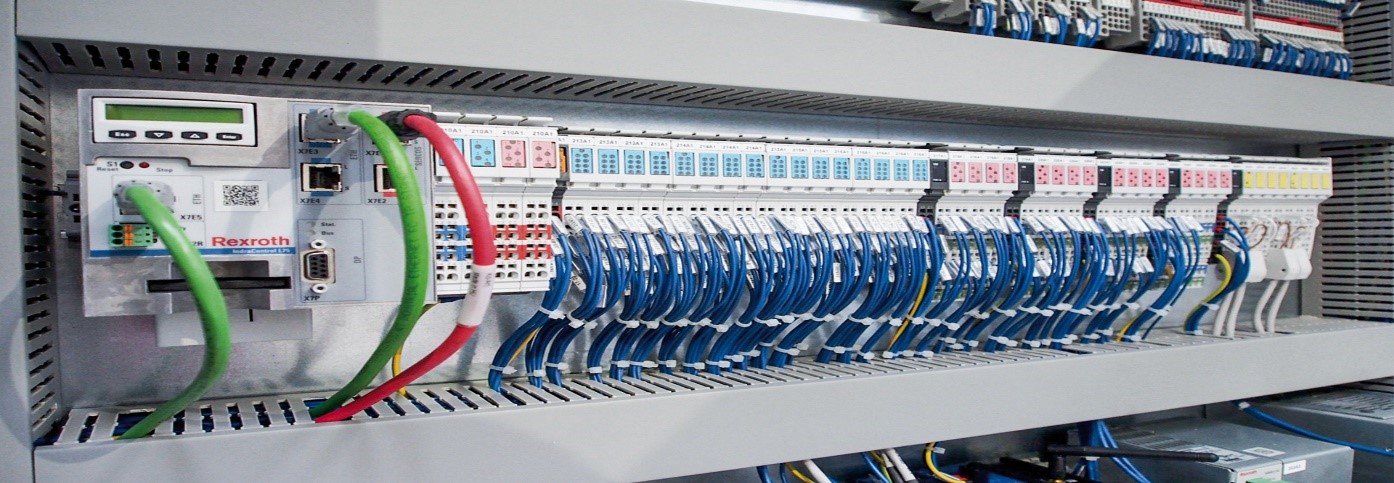

PLC Automation Systems

Mechanic Automation /Robotics Department-Automation Products

We can achieve communication between all our products using any PLC brand with most common protocols as well as the supply and after-sales services for PLC’s in IEC 61313-3 standard.

It has been almost half a century since the invention of first PLC with a fixed program consisting of hundreds, even thousands of relays. It was almost impossible to find not only people who can understand these PLCs but also spare parts. Costs were so high that companies could go bankrupt. We respect those who carried out manufacturing, contributed to our country’s economy and provided employment in the times when no one knew PLC software or spare parts were hard to find. Today, almost all large to small industrial companies use Automation systems with PLCs. PLC manufacturers offer groundbreaking innovations in hardware and software to industry each passing day with the experience of years and the advancement of technology. We live in the technological age when even end-users can program PLC and PLC spare parts can be supplied on the same day. It is possible to achieve security, speed, continuity and quality in production and manufacturing equally with the right suppliers.

As HKTM A.Ş., we offer supply and after sales (programming and training) services to end-users or manufacturers with our 15 years of automation experience. Operating as authorized service and dealership of quality products in industrial automation, our company shares its after-sales technical support and experiences with its customers. HKTM A.Ş. is one of the few companies that can offer PLC, programmable safety relays, light barriers, sensor and related products in Industrial Automation and Robot, Servo drive-motor, Electric Welding, screwing, linear motion systems, reducer and fitting equipment, hydraulic and pneumatic planning and product supply.

We can achieve communication between all our products using any PLC brand with most common protocols (Profinet, Profibus, EtherCat, Ethernet/IP and SercosIII) as well as the supply and after-sales services for well-known PLC brands in the market in IEC 61313-3 standard. We share program infrastructure (Robots, Servo drive, RFID, PID, etc) applications prepared specifically for products with our customers as open source. We prioritize occupational safety as well as machine and product safety in all systems that we commission in high safety standards. We actively offer product supply and after-sales services to leading companies in household appliances, automotive, iron and steel, food and manufacturing industries.

We carry out sales, planning, commissioning of servo drive-motor, robot, electric welding, hydraulic, pneumatic product groups, and revision of all systems containing these product types or turnkey projects.

Sectors we actively operate:

Adhesion, grouping, quality control, source lines, sheet metal sliding, slitting, transfer systems in household appliances,

Robotic and manual MFDC welding systems, paint lines, transfer and quality control applications in Automotive,

Arc furnaces, Ladle furnaces, Crucible furnace, Energy Saving, hydraulic press, shears, sheet metal sliding, slitting line automation in Iron and Steel,

Filling, packaging, transfer and grouping systems in Food

and revision of all these systems.

.jpg)

Parts Processing and Cutting

Mechanic Automations /Robotics Department-Robotics Systems

We produce robotic solutions that can do many cutting and processing procedures including complex components by providing tailor-made softwares.

We can offer economic and highly efficient solutions for a wide range of cutting and processing operations including complex parts thanks to robot based cutting and processing solutions.

Processing operations that take longer with conventional processing machines can be carried out in a shorter time and with almost no human intervention thanks to robot based systems. Detailed operations can be carried out in complex parts using positioners running in integration with robot manipulators.

Depending on the desired project, high speed spindle motors, spherical and conical cutters, cooling systems, automatic chuck replacement systems and many more system elements that may be required can be configured according to the needs of our customers by our professional team.

.jpg)

Electrical Cylinders

Mechanical Automation-Automation Systems

Electromechanical cylinders provide a higher performance alternative and energy efficiency compared to the pneumatic and hydraulic cylinders. Such actuators can be utilized even at high powers.

Electromechanical cylinders which offer the advantages of modern control technologies are a high-performance alternative compared to pneumatic and hydraulic cylinders and they rank the highest when it comes to energy efficiency. Such actuators can be utilized even at high powers. Parameters of force, position and drive speed can be adjusted as desired by the user and adapted to new tasks in a flexible manner through the drive system at any time.

.jpg)

Assembly Systems

Mechanic Automation /Robotics Department-Mechanical Products

We offer solutions with assembly tables consisting of aluminum profile systems, transfer lines and accessories groups for our customers.

We offer solutions with assembly tables consisting of aluminum profile systems, transfer lines and accessories groups. Working efficiently in Assembly Lines is the main objective of the modern production facilities. Assembly lines where the Bosch Rexroth products are used are developed according to simple production principles. This allows for simple and quick planning and execution for efficient production systems. These complicated systems allow for minimum time wasted and maximum efficiency for operator assembly, thus allowing savings for manpower and time.

As HKTM, whether it be minimal cycle times in most accurate allocation, fast changing aimed at small product batches or flexible adaptation according to the changes in production, you can trust in Bosch Rexroth to create the idea interaction between automation solutions and all drive and control technologies according to your needs.

Assembly systems comprise of TS1, TS2, TS5 and Varioflow, Active Mover Transfer systems.

.jpg)

Servo Motor Drive System & Maintenance

Mechanic Automation /Robotics Department-Automation Products

We create solutions for servo driver and servo motor according to your needs and provide services for maintenance of servo motors with our technical expert staff and experienced suppliers.

In electric drive and control systems, servo drive and motor applications are the most common applications. Servo drive and motor applications that offer high control and precision are commonly used in various areas of industry. HKTM A.Ş. that has a wide range of products in servo systems offers turnkey, revision and after-sales support services with quality servo system solutions that can be adapted to all systems that it operates as a dealer. Offering economic, quality and successful servo system supply for 15 years, HKTM A.Ş. has been the first choice of manufacturers and end-user firms.

Supplier with high technical expertise and experience is significant when choosing a servo system. The supplier must ensure cost and performance advantage with suitable servo system selection and provide continuity with after-sales training, technical support, spare parts and repair services.

Revision

Organizations that use machines with servo systems of various brands must choose technological and quality products for the continuity of manufacturing and production. Users that cannot receive sufficient technical support and spare parts services prefer low-cost system revisions. We complete the commissioning operation for servo system revisions with affordable investment costs using drive motors suitable for available system structure in a few days. We also carry out projects that pay off the investment cost in a short time with the servo system hydraulic pump drive applications in “Energy Saving” area. Thanks to this application that is becoming common in hydraulic presses, Plastic/Metal injection molding machines and industrial hydraulics, costs are paid off and energy saving is achieved in the short term. It takes only one day to commission this application that is sold as a ready package with the pump connected to servo motor.

Turn-Key Systems

We produce turnkey machines on servo system production lines or auxiliary systems. We offer turn-key, design and commissioning services in adhesion, grouping, transfer, handling, cutting, printer marking and packing systems. We produce economic systems by offering customer-specific solutions in the projects carried out in-house in all stages in our factory with the experienced teams. Guaranteed and high security equipment is used in all projects that we use quality products.

After-Sales

We offer after-sales, technical assistance, spare parts and repair services for all products used in revision or turnkey projects. We commit to high quality for manufacturing industry while establishing trust for the customer as the only contact in any case. We carry out guaranteed original parts replacement and repair operations for servo drive and motors that we are dealers for. All servo motors repaired by technical team with overseas training and accreditation are under international warranty. Also, manufacturing continuity is achieved in cases of failures with trainings aimed at maintenance and failure diagnosis.

HKTM A.Ş. with high experience and quality service approach in servo system applications has become a well-known brand with projects carried out domestically and in other countries.

.jpg)

Pneumatic Products

Mechanic Automation /Robotics Department-Automation Products

We provide fast supply for everything from robotic systems to factory production lines thanks to our company stock; we have everything you need from the project design to production.

Derived from Greek word “pneuma” which means wind or breath, pneumatic can be described as the study of engineering and science investigating movement and control of mechanical systems operating with pressurized air.

Pneumatics dates back to 2500 years ago when air bellows were used. Although pressurized air is one of the most important energy types that humankind discovered at early ages and began to use, it was not used in power applications in a systematic way until the mid 19th century. Hand tools, locomotives and similar power systems pioneered the development and rapid spread of pneumatics .

Pneumatic applications are widely used in control systems in todays industry. From construction machinery to robotic systems, factory production lines to works that manpower is not enough, it is used in almost all manufacturing, assembly and operation lines.

Why Pneumatics?

Demand for pneumatic systems has gone up as they have advantages over electrical and hydraulic systems. Basic energy generation and transmission is accomplished by air in pneumatics. Air is a resource that can be easily found everywhere, easy to transfer and store when pressurized. It is also not sensitive to changes in heat. Thus, it is easy to use these systems in high temperatures. Use of the air as a power source is safe. There are no such risks as flare, explosion or combustion . Another safety element in pneumatic systems is that system automatically stops in the case of overload. Operation continues when overload is eliminated. Environmental awareness in industrial plants is improving day by day. Pneumatic must be considered as a clean power source as it does not waste and cause environmental pollution even in cases of leakage.

Disadvantages of Pneumatics

As air is a highly compressible fluid, it does not perform as high as hydraulic system to generate power. For the same reason, positioning accuracy is reduced and it becomes difficult to get a constant and uniform speed. Air from the compressor must be cleaned, dried to dehumidify and filtered before using. This means more energy consumption and increase in costs. Pneumatic systems are quite noisy if not used with appropriate equipment.

Pneumatic systems are commonly used in every industry:

- Mechatronics Systems

- Automation systems and electronic industry

- Robot Technology

- and forming operations such as rolling, bending and drawing are some of these industries.

As HKTM A.Ş., we can offer project, sales and after-sales technical support in all areas that pneumatics is used with our experience in iron-steel industry and sample projects in robotic automation.

Resistance Welding Technology

Mechanic Automation /Robotics Department-Automation Products

MFDC resistance welding units used in automotive and automotive sub industry as well as white appliances sector provide significant energy savings compared to AC welding systems.

Commonly used in the automotive and automotive supplier industry, resistance welding systems have also been common in household appliance industry. HKTM A.Ş. that supplies AC and MFDC (medium frequency) resistance welding units and transformers in this field is one of the leading companies in the industry with its after commissioning support services. HKTM also plans robot or servo system AC and MFDC welding system revision and turnkey lines apart from resistance welding systems. AC welding systems are suitable for medium and low quality operations. They are more economic when compared to MFDC unit but they have high energy costs. For these reasons, it gradually gets less demand in automotive and automotive supply industry.

Medium frequency (MFDC) welding systems offer better quality results with less energy. MFDC welding systems that pay off the investment costs in a short time with the energy savings they offer are the most preferred resistance welding systems today. MFDC systems also include current, voltage, resistance (UIR) regulated adaptive control application. With this application, initial welding quality can be achieved even in variable environments. Adaptive control application that is only minutes to install and commission is used in production lines that require high quality.

Spot, Projection and Seam welding operations can be carried out with AC and MFDC systems. Our welding units programmed using software installed on the PC or using an external panel offer the highest quality in simple and complex welding operations. Different guns as well as PLC control with wide protocol support can be used to work with our units that also include ready robot infrastructure. It is possible to connect to many units via computer with external Ethernet card option.

We continue adding quality value to Automotive, Household Appliances and assembly industries with welding systems proven in the industry and our experienced teams.

Screwing and Tightening Systems

Mechanic Automation /Robotics Department-Automation Products

Precision and continuity in screwing quality directly affect the quality of the product. Electric screwing offers better quality results compared to pneumatic screwing and 50% energy savings can be achieved.

Electrical screwing systems are used in many industries and in particular in automotive and assembly industries. Precision and continuity in screwing quality directly affect the quality of the product. Electric screwing offers better quality results compared to pneumatic screwing and 50% energy savings can be achieved.

HKTM A.Ş. addresses a wide range of area of utilization with electrical screwing units and tightening tools it supplies. While screwing units support communication in common protocols, we can offer solutions for all industries with expandable hand units options. We can offer the most precise solution even in variable production lines with manual, semi-automatic or fully automatic expandable tools

High quality standard can be achieved even in manual stations with intuitive programming interface in screwing units that have VDI/VDE 2862 fastening standard used by automotive industry. It is also possible to keep quality control level high with reporting feature for each tightening operation.

With its products of high safety level that appeal to a wide range of area of utilization, HKTM A.Ş. offers services to leading companies of the industry in electrical screwing systems.

Sensors, RFID & Fieldbus

Mechanic Automation /Robotics Department-Automation Products

Sensors are used in almost all areas of our lives and became indispensable. Increase in the quality and quantity of information in the field accelerated the development of new fieldbus technologies.

Sensors are sense organs of automatic control systems just like the human sense systems used to sense the environment.

Sensors are used in almost all areas of our lives and became indispensable. We can use sensor technology to carry out works that we previously could not even carry out or required complex or expensive systems in a much more simple way.

Sensors that are used in various places such automatic doors and car park sensors in our daily lives offer similar solutions for industry just like offering simple solution methods such as safety, energy savings, low cost and simple solutions they offer.

We can carry out many sensing operations such as temperature, pressure, flow, level, length, area, metal in a system that is desired to be assembled. We can offer alternatives in issues such as cost, safety, simplicity by offering different solutions with different sensing techniques/products depending on machine or system needs.

As HKTM A.Ş, we can offer simple, safe, accurate and low cost solutions by recommending the most suitable products for your machine/systems or with the projects that we offer according to needs with our experiences in projects.

RFID

Radio Frequency Identification (RFID) technology is used to identify and monitor all live or stable objects from a distance without contact. Use of RFID, a technology that's quite old, dates back to the World War II.

RFID technology consists of three basic components:

- RFID Tag

- RFID Printer/Reader

- Programming Tool

RFID is gradually spreading out to the world and in our country and it is used in many industries. Automotive, fuel, logistics, retail, agriculture, health, medicine, textile, finance, banking, energy, government, manufacturing, security, tourism are some of the industries that RFID is actively and widely used.

RFID technologies significantly reduce operational costs, accelerate work flows, increase productivity and profitability.

We can offer support with safer, fast and traceable solutions that eliminates human factor in your process with RFID technology that we can offer as an alternative to systems you want to design. You can access production information for your device every time you want in the systems we will install, eliminate mistakes that operators can make in the supply chain, make your production more productive and enter your storage details accurately.

Special Solutions

Mechanic Automation /Robotics Department-Robotics Systems

We produce cost-effective and reliable turnkey systems with our machinery and line solutions for mechanical automation and robotic systems.

We produce economical and reliable turnkey solutions that meet customer demands fully with machine/line solutions created in line with customer demands and needs.

We integrate our design and production experience gained through applications in various industries with turnkey solutions aiming to meet customer needs and demands in the most accurate way possible.

Some industries that we operate for specific applications:

- White Appliances Industry – Ceran Adhesion Line

- White Appliances Industry – Front Panel Adhesion Line

- White Appliances Industry – Panel Adhesion Line

- White Appliances Industry – Stove Adhesion and Grouping Line

- White Appliances Industry – Profile and Bracket Adhesion Machines

- White Appliances Industry – Oven Sandwich Door Adhesion Machines

- White Appliances Industry – Stove Glass and Frame Adhesion

- White Appliances Industry – MFDC Tray Welding Machine

- White Appliances Industry – MFDC Basket Welding Machine

- White Appliances Industry – Sealing Machine

- White Appliances Industry – Hinge Grouping Machine

- Electric Switching Products – Laser writing before packaging

- Electric Switching Products – Laser writing in separator

- Electric Switching Products– Separator Supply/Product Unloading System

- Plug Cable Production – Holder Driving System

- Food and Packaging Industry – Packaging and Palletizing System

- Food and Packaging Industry – Visual Control System

Palletizing

Mechanic Automation /Robotics Department-Robotics Systems

We provide specific projects for all stages of robotized and automation based palletizing procedures, from feeding to transporting.

We offer flexible, economic and reliable solutions suited for needs with our experience and knowledge in Palletizing and Palletizing automation.

We produce wide range of solutions such as cartesian robot or serial robot (4/5/6 Axis robots) by identifying the most suitable solution based on the desired application.

We work towards determining the most suitable solution for our customers by understanding customer needs thanks to these wide range of products for which we have design and production experience.

Hydraulic Automation

Hydraulic Automation-

We provide continuous service to our customers from a single source with specific solutions by making the complementary automation for the hydraulic systems we have established.

Hydraulic systems that offer power and control together are used in various industries in various areas. Hydraulic applications can be seen almost in all industries such as cars, planes, boats, agricultural machines, work machines, at ports, in the entertainment industry, space exploration, dams, etc. Hydraulic has been indispensable part for our industry and technology with a wide range of applications.

HKTM A.Ş. offers planning, sales and engineering services in Industrial and Mobile Hydraulic areas with its 15 years of experience. We also provide quality solutions in revision and turnkey projects by offering product and software support in hydraulic automation.

Industrial Hydraulic

Our company that operates in Iron and steel sector, automotive, household appliances and energy and provides solutions in accordance with customer needs with hydraulic control systems and software support. We produce high precision applications with PLC based hydraulic control units produced for industrial hydraulic systems. We offer software support with Arc furnaces, Ladle furnaces, Press automation, simulation cabins, entertainment industry, hoisting-and-transport systems automation and safety equipment. Our company with experienced staff with overseas training/education has completed prestigious projects in drive and control area with hydraulic solutions performed using top quality products.

Mobile Hydraulic

Compact products with high protection class that can perform in heavy operation conditions are required in Mobile Hydraulics when compared to industrial hydraulics.

Although Hydraulic Automation Operation logic is similar, mobile hydraulic products are manufactured differently from industrial products. Mobile hydraulic control units and control panels are manufactured to work in heavy conditions. Hydraulic control systems are commonly used in mobile sector as they have outputs capable of directly driving analog valves (PWM Frequency), they are fully closed and in IP67 protection class and they are capable of operating in all temperatures and weather conditions. HKTM A.Ş. offers turnkey and revision services in various industries with its wide range of products and experience in mobile hydraulic and control. We mainly offer mobile hydraulic drive and control solutions for construction machinery, agricultural machinery, defense industry, commercial trucks and vehicles. As our mobile hydraulic control units are produced with high protection standards, they provide highest level of human and vehicle security.

HKTM A.Ş. that has completed significant projects in Industrial and Mobile Hydraulics offers safety and quality to its customers from software support to training.

Automation Panels

Hydraulic systems-

We also design and assemble the automation panels of the hydromechanical and automation systems we do the installation for.

We are also able to make the automation panels, project planning and assembly of all turnkey hydromechanics and automation systems which we produce ourselves.

SVP Applications

Hydromechanics Systems-

With the dynamic performance provided by the servo variable pump driven system (SVP), companies can achieve efficiency in their hydraulic systems for years.

SVP (servo variable displacement pump drive system) consists of hydraulic pump driven by synchronous servo motor. With SVP, pressure, flow rate, position control and force control can be made as well as dynamic performance and closed-circuit accuracy.

Hydraulic Cylinders

Hydromechanics Systems-

With our experience in hydraulic cylinders and application areas, we produce hydraulic cylinders according to customer needs determined by field expertise.

As Motion Control Technologies Center, we produce hydraulic cylinders customized for our customers by combining our know-how and field experience with regard to hydraulic cylinders and their application areas gained over more than 20 years with the manufacture and test lines in our factory.

.jpg)

Valve Control Blocks

Hydromechanics Systems

Valve block types that equip various modular valve types that are compliant with international standards to the system are delivered immediately from our stock.

We design and manufacture valve control blocks up to 4.000 kg made of GGG40 nodular cast iron or aluminum with which generally direction, speed and pressure adjustment of the control element is made and which combine the valve groups.

.jpg)

Hydraulic Power Units

Hydromechanics Systems

We are able to respond to special requests from 20 lts to 40.000 lts with the hydraulic power units detailed by our project engineers.

In accordance with the system requirements demanded by our customers, we produce hydraulic power units that are detailed by our project engineers and have a storage capacity between 20 - 40.000 L.

.jpg)

Valve Stands

Hydromechanics Systems

Design and project stages of valve control blocks and valve control stands are done by our team of valve stand experts.

We produce valve stands whose features are determined by our project engineers and which are detailed by our design team, and which contains the valve control blocks suitable for requirements of the system.

.jpg)

Test Systems

Hydromechanics Systems-

We design and produce systems that can perform the position control tests as well as function, pressure, leakage tests of hydraulic valves.

We design and produce systems that can perform the position control tests as well as function, pressure, leakage tests of proportional or on/off hydraulic valves.

.jpg)

Filtration & Circulation Groups

Hydromechanics Systems-

We develop and produce application focused solutions in order control both internal and external factors.

We create application-oriented solutions for groups in which circulation pumps, online filters, filters and coolers are used in series connection in order to control the cleanness and temperature of oil in hydraulic systems.

.jpg)

Battery - Nitrogen Stands

Hydromechanics Systems-

We produce systems that are designed to be used in emergency requirements involving the collectors of bladder hydraulic batteries or nitrogen tubes with piston batteries.

We produce systems that are used to collect the pressurized oil generally in order to use it for emergency situations, in which piston accumulators and nitrogen tubes or bladder hydraulic accumulators are combined by connecting with collectors.

.jpg)

Load Platforms

Hydromechanics Systems

With our expertise and experience gathered from different sectors; we provide solutions and projects tailor made for your business.

We make turnkey project design and production of load platforms customized according to customer expectations. Our experience gained from different sectors and expert staff optimize your work-specific projects.

.jpg)

Special Hydraulic Presses

Hydromechanics Systems-

We are the solution partner of our customers for special hydraulic presses detailed and designed according to the requested application and sector.

We are the solution partner of our customers for special hydraulic presses detailed according to the requested application and sector and in general designed for up to 2 to 10 tones.

.jpg)

Special Solutions

Hydromechanics Systems-

With technical infrastructure, experience and expert team we have built as HKTM, we create new solutions and products in every area where movement control systems are required.

With technical infrastructure, experience and expert team we have built as HKTM, we create new solutions and products in every area where movement control systems are required.

.jpg)

Motion Control Applications

Mechanics Automation / Robotics Department-Automation Systems

We are at your service with high performance solutions in sheet metal drive, decoiler, flying shear systems as well as slitting, transfer, grouping, printer, marking source systems.

We offer solutions in driver-based sheet metal drive, opener and flying shear systems as well as slitting, transfer, grouping, printer, marking source systems. We are at your service with high-performance solutions in applications up to 64 axes.

.jpg)

Linear Motion Systems

Mechanics Automation /Robotics Department -Mechanical Products

These are systems moving on a straight line at fixed/variable speeds. We offer solutions with assembly tables, transfer lines and accessories groups.

As its name implies, these are systems moving on a straight line at fixed/variable speeds. We offer solutions with assembly tables consisting of aluminum profile systems, transfer lines and accessories groups.

.jpg)

Bonding Lines

Mechanics Automation / Robotics Department -Robotics Systems

We provide tailor-made solutions with adhesives with different specifications at either single or double components that can be applied accurately at all tolerance ranges.

We produce bonding lines customized to needs, especially for the white goods sector, with single or double component bonding agents and sealers with different technical specifications that are precisely applied to desired positions at low tolerance intervals.

.jpg)

Food Packaging Applications

Mechanics Automation / Robotics Department -Robotics Systems

In food production lines that require high hygiene, we make it possible to pack fully automatically with our specially produced systems using robotics and other expertise.

In food production lines that require high hygiene, we make it possible to pack fully automatically with our specially produced systems using robotics and other expertise.

Transportation, Packaging

Mechanics Automation / Robotics Department -Robotics Systems

We provide adjustable, cost-effective and reliable robotics system solutions for transportation and packaging of all sectors.

We offer flexible, economic and safe turnkey solutions for robot packing and crating solutions best suited to customer needs.

Especially thanks to turnkey solutions produced in fields that require high speeds, we work towards meeting customer needs with flexible and economic solutions.

We produce solutions best suited to customer needs with high speed solutions such as Scara, Delta as well as simpler systems such as Cartesian robots and serial robots (6 Axis) depending on the application.

We offer solutions specific to your application in many areas such as holders designed for the product, box and separator opening systems, conveyor and separator systems.

When required, we design special systems to meet customer needs by supporting these systems with visual control and artificial vision systems.