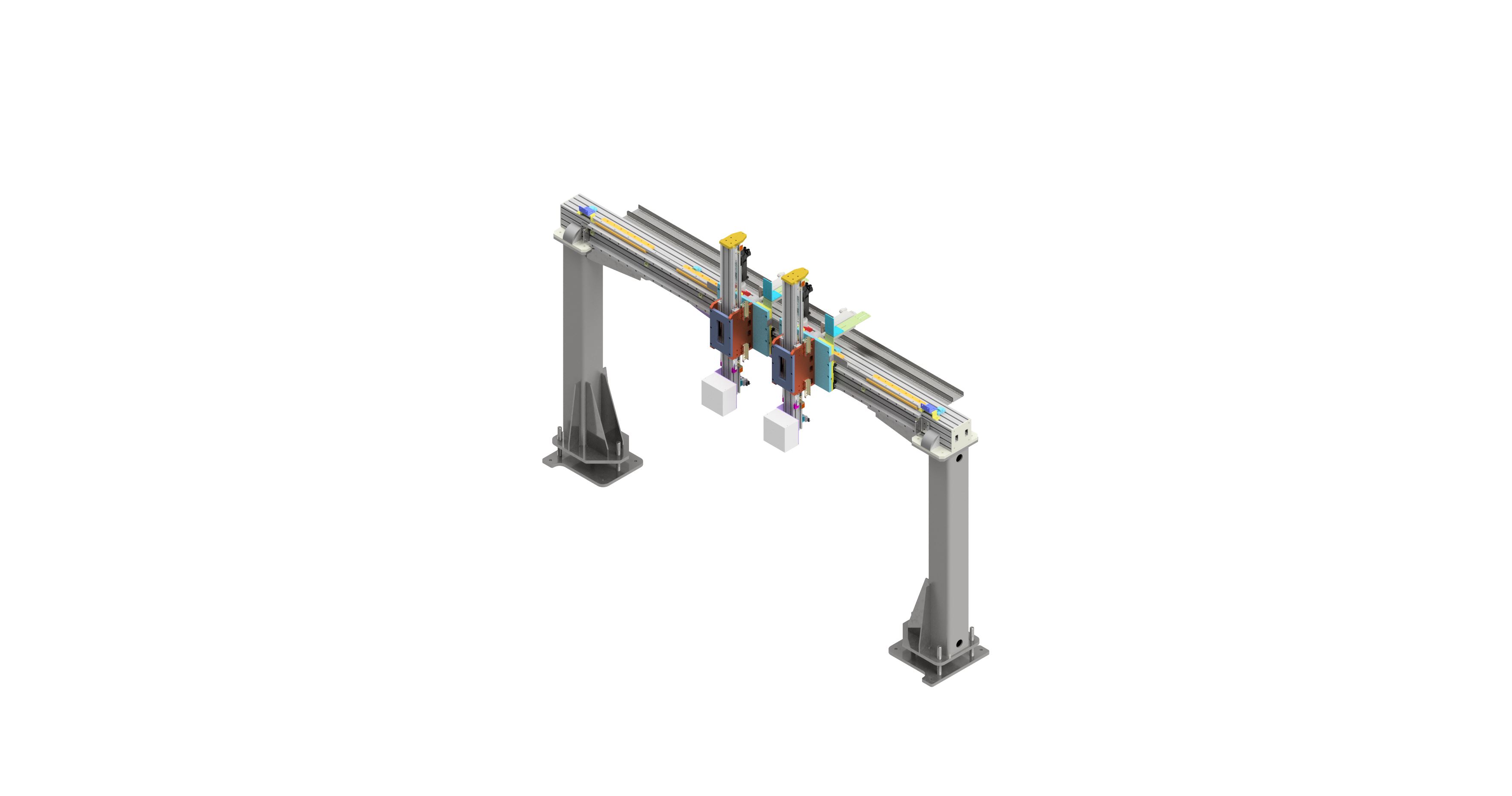

Cartesian Robots

Another name for the cartesian robots is linear or gantry robots. A cartesian robot is defined as robots that move along the X, Y and Z coordinates. There’s generally a pulley system and it provides movement on the X and Y axes on the pulleys or, when stationary, provides up and down movement on the Z axis.

Cartesian robots are generally large systems that undertake collection and stacking duties. But they can be used in different operations such as welding. Cartesian robot systems provide particular advantage in businesses with large work areas and in factories with correct and fast positioning and placement.

Thanks to their correct positioning ability, they are able to place the correct components to the correct places with less error margin, which is crucial for businesses that conduct large scale mass production. The movements of cartesian robots, or the Gantry robots, are easier to program compared to the other robots. This is due to the fact that they are moved on a simple X, Y, Z axis. Another advantage of theirs is how little they are affected by the limitations regarding the floor. Thanks to this, their assembly is easier compared to other robots.