Magnetic Couplers

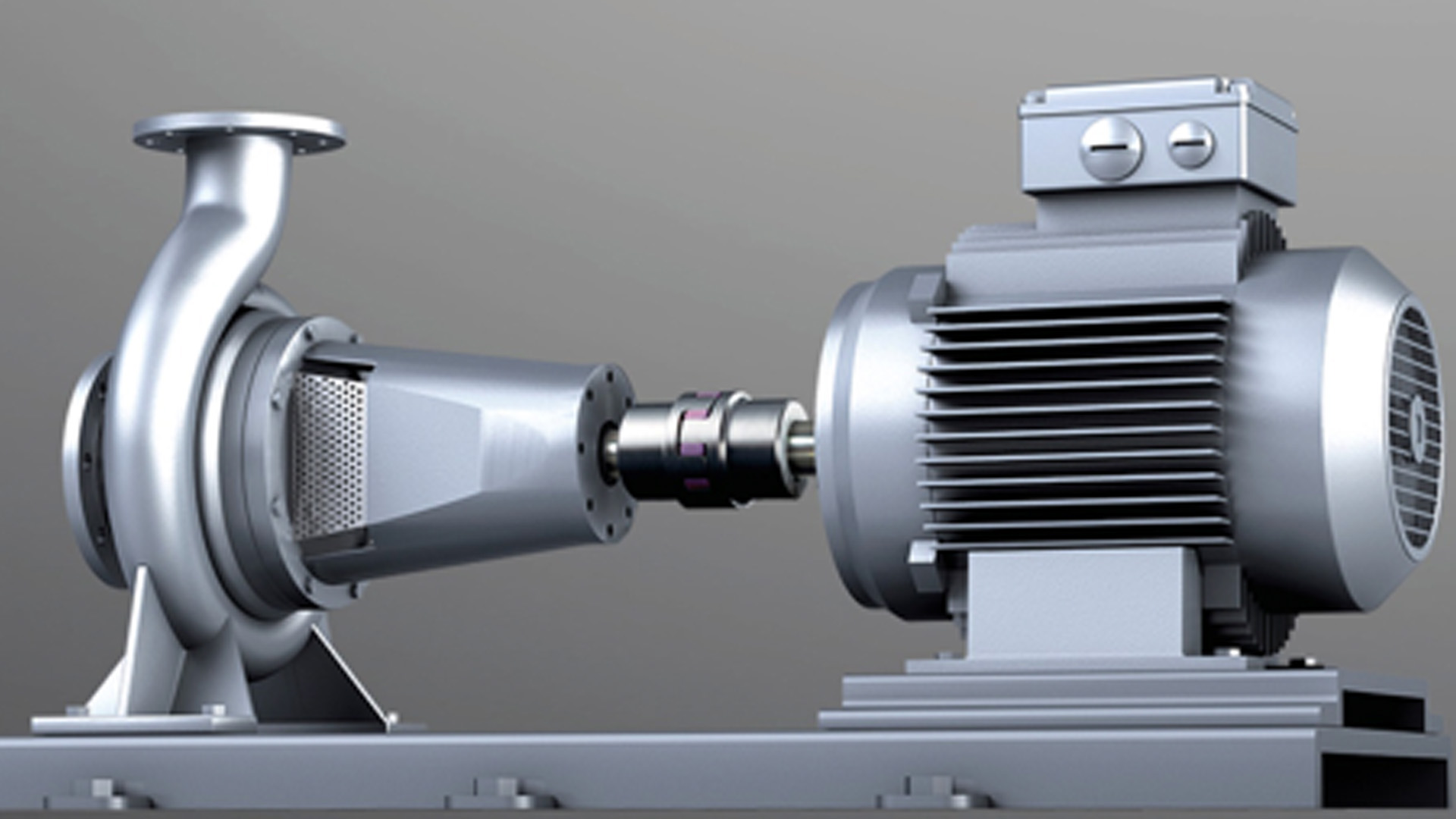

Magnetic couplers are designed to transfer the current torque from one shaft to another. However, what separates magnetic couplers from other applications is the fact that they do this without a physical or mechanical connections. This transferring method is highly suitable for liquid pumping. The magnetic couplers are used commonly where leakage problems are found prominently.

An advantage of the magnetic couplers compared to other application couplers is, since there is no contact between the components during the accouplement, wear and tear is nearly non-existent. In case of overloading on the coupler, the magnetic couplers switch to the next position and has an internal security feature that provide continuity. Since the couplers are used with fixed magnets, they do not require and external power source.

Magnetic couplers are typically used in applications where there are low torque loads, phased initiation or where the drive side of the system has very low rotational inertia. Also, considering the low torque loads, their dimensions are quite large. The couplers also have moderate radial loads on the support bearings.

The torque transfer happens in a clean and efficient way in the magnetic couplers, the torque loss is very low. Since there is no wear and tear, the service life is long and the maintenance costs are very low. It ensures that the product and the atmosphere are completely leakage-proof. Insulation is achieved via smooth seal or ring and thus, the need for dynamically loading the sealing elements is eliminated and since there are no friction surfaces, 100% insulation is achieved.