Assembly Technologies

Products perfectly compatible with each other allows you to create extremely economic systems in Assembly Technology. From ergonomic work stations to highly automated manufacturing and transfer lines, we provide the best “assembly experience” for your manufacturing processes.

We can analyze assembly technologies under three main titles and as detailed below.

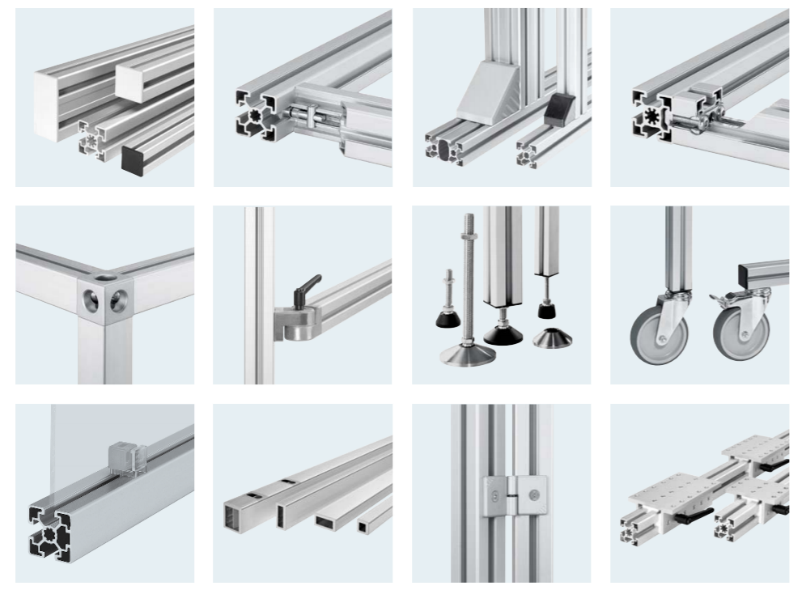

Basic mechanical elements, thanks to various sigma profiles and assembly elements, HKTM offers many different products for basic structures for shelves, cabinets, benches, work stations, machine skeletons and protective barriers. Lightweight, well-designed aluminum components can reduce planning and assembly costs, are re-usable and reconfigurable. Our system that was introduced by Bosch Rexroth 30 years ago now encompasses over 1,500 parts.

The idea is outstandingly simple: the system is based on aluminum profiles with “infinite” vertical slots. Thanks to comprehensive service support including systematic improvements, customer focused services and free of charge planning software, our modular system provides everything you need for efficient work environments.

Manual production systems, Working efficiently in Assembly Lines is the main objective of the modern production facilities. Bosch Rexroth’s manual production systems were developed with strict adherence to simple production principles. This allows for simple and quick planning and execution for efficient production systems. These complicated systems allow for minimum time wasted and maximum efficiency for operator assembly, thus allowing savings for manpower and time.

Transfer systems, HKTM creates transfer line projects using Bosch Rexroth modular conveyor systems. Transfer system is the system that carries work pieces over from one station to another on the assembly line. Two constantly moving belts, gear belts, smooth chains, chains with pulleys or circular rolls carry the work piece on the conveyor using friction. These systems carry the product from one point to the designated point. During this process, the product may be subjected to various assembly processes depending on the status of the work. Structures of the transfer systems are explained below.

TS1 Transfer System

TS1 Transfer Systems are belt conveyor systems that are small and are used with maximum product weight of 3kg. Again, it can be used in cases where the product sizes are <160x160(mm). Their common use cases are food, medicine sector and assembly lines of such small sized products.

TS2 Transfer System

TS2 Transfer Systems are conveyor systems that are operated by belts, plastic chains or steel chains depending on the weight of the product, they are also small and are used with maximum product weight of 240kg. The can be used in cases where the product sizes are <1200x1200(mm). Their common use cases are electronics, white appliances sector and assembly lines of such products.

TS5 Transfer System

TS5 Transfer Systems are roller conveyor systems that are small and are used with maximum product weight of 400kg. The can be used in cases where the product sizes are >455x455(mm). Main areas of use are white appliances, automotive sector and the assembly lines compatible with these weights.

Vario Flow Transfer System

VarioFlow plus system is more commonly preferred in the appliances that require high speeds. It is used in cases where the maximum product weight does not exceed 18kg’s. Provides a high performance, standard and many faceted conveyor system for Food and Packaging applications, Health applications, Automotive and Electronic assembly line applications.

Active Mover Transfer System

Active Mover linear motor transfer system can be used anywhere, where the products have to be carried quickly and in a sensitive way. This encompasses many assembly applications in the automotive sub sector, medical technology and life sciences for the Active Move electronics manufacturing. Provides drive forces up to 160 N per pallet robust design for easy process integration and various applications. The system is able to carry up to 10 kg’s per product and can speed up to 150m /min.

Assembly Technologies Kullanılan Projeler