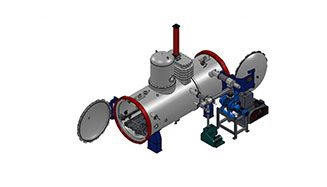

Hydraulic Power Units

Hydraulic systems are systems created to provide linear, circular and angular movements with hydraulic energy, and much of the industrialized world today depends on hydraulic systems. Hydraulics are present in every systems where there is movement control. The hydraulic power units produced primarily for iron&steel, industrial, mobile and marine applications by HKTM, have various pressure and flow rate, reservoir capacity, material and fluid compatibilities. The systems that have their technical specifications set by project engineers can be produced with compact and specific production power unit options. The HKTM hydraulic power units that are generally comprised of pumps, reservoirs, drainage valves, filters, level indicators and vents provide reliable power to hydraulic systems. Behind every HKTM hydraulic power unit is good engineering support as standard in order to live up to our good engineering motto.

Hydraulic Valve Blocks

Hydraulic valve blocks are made of GGG40 nodular cast iron or aluminum with which generally direction, speed and pressure adjustment of the control element is made and which combine the valve groups, and in short, are the most critical components of the movement & control group of the system.. HKTM Hydraulic blocks are designed and manufactured specifically for each customers’ appliances. The entire control block is handled by the engineering approach most suitable for the project. HKTM Hydraulic blocks can be delivered as bare blocks or in valve stand form where the hydraulic block is mounted on a chassis. All HKTM valve blocks are subjected to function tests before delivery. Whether or not each valve works is checked in these tests. Then gets made ready for delivery after setting for project values.

Hydraulic Cylinders

Hydraulic Cylinders are the circuit elements that turn hydraulic energy into mechanical energy, thus creating linear movement and force. Hydraulic cylinders are used in different type and scales today. These are designed specifically for their purposes such as single action, dual action, tandem and telescopic, and are used as such in their applications. As Motion Control Technology Center, we produce customized solutions for our customers by combining our know-how and field experience with regard to hydraulic cylinders and their application areas gained over more than 20 years with the manufacture and test lines in our factory.

Servo Motor Driven Hydraulic Systems

Since the energy sources of the world dwindle each day and energy costs rise accordingly; efficient usage of power has become a much more important matter. In parallel with this, power efficiency has been a growing concern for hydraulic systems in the recent years, and there are new systems developed to match this purpose.

In a standard driven hydraulic system, the hydraulic pump (fixed or variable displacement), is driven by an asynchronous motor that is rotating at a fixed rate and is connected to the mains frequency. It is provided by the valves on the control and power transfer hydraulic system, or occasionally, control valves on the variable displacement pumps. Asynchronous motor converts the electrical energy to mechanical energy (for hydraulic pump). The electric motor is not expected to provide any other functionality. In a variable speed pump driven system, the hydraulic pump is driven by a servo motor. The hydraulic only provides the power transfer. Rotational drive speed of the pomp is controlled by the amount of fluid sent to the system proportionally.

Electronic side of drive has two functions.

Energy supply: Controlling the flow and pressure of the system by altering the rotational speed of the motor unit. Thus, it provides control and adjustment functions of the electric axis. Drive part of this system is comprised of the servo motor and the servo driver required for driving this motor.

In the pump part, units with fixed or variable displacement that can be operated in two or four sections depending on the open or closed circuit hydraulic system that will be used. Servo motor drives the fixed displacement (variable displacement) pump. Output flow rate of the system is achieve via multiplying the displacement of the driven pump with the pump rotation of the servo motor. System pressure is measured by the pressure sensor attached to the pump pressure line. Controls are done by the software within the controls. Has high operation dynamics. It is possible to control force, speed and position very accurately.

Hydraulic Power Units Kullanılan Projeler